3M will: Discontinue all PFAS production by the end of 2025: 3M will discontinue all fluoropolymers, fluorinated fluids, and PFAS-based additive products. We will help our customers make the transition in an orderly manner. 3M intends to meet its current contractual obligations during the transition period.

PFAS include HFE7500, HFE7200, HFE7100 series of fluorine oil products.

Emulseo introduces a replacement product, Fluo-Oil 135, which offers consistent stability, reliability, and good molecular retention, ensuring that your project experiments run continuously without interruption.

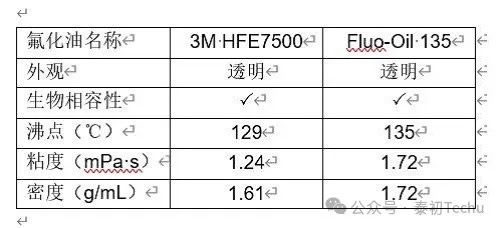

The parameter comparison between Fluo-Oil 7500 and HFE7500 fluorine oil is shown below:

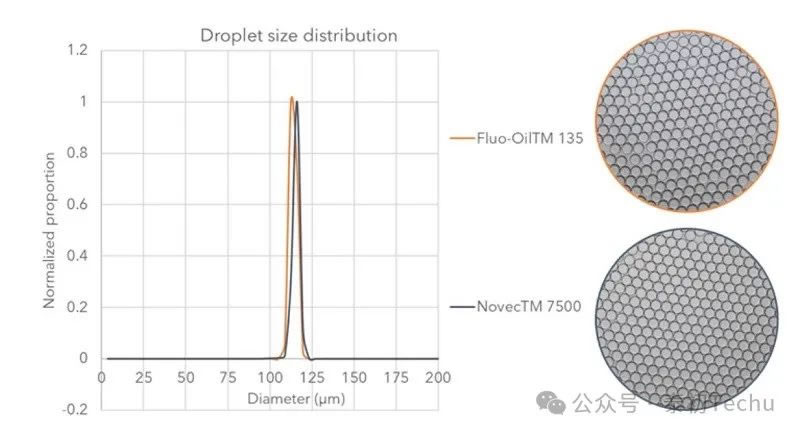

Comparison of droplet-producing performance with 3M HFE7500 oils

FluoSurf neat surfactant was diluted with 3M HFE7500 and Fluo-Oil 135 fluorinated oil, respectively, to obtain a mass concentration of 4 w/w%.

Two-phase flow rate generated by water droplets or water in oil droplets:

The flow rate of the oil phase was 5 μL/min and the flow rate of the aqueous phase was 1.6 μL/min.

PBS solution or PBS solution with 100 μM fluorescein in the aqueous phase (to test for leakage of droplets)

Inverted microscope observation and Image J software analysis.

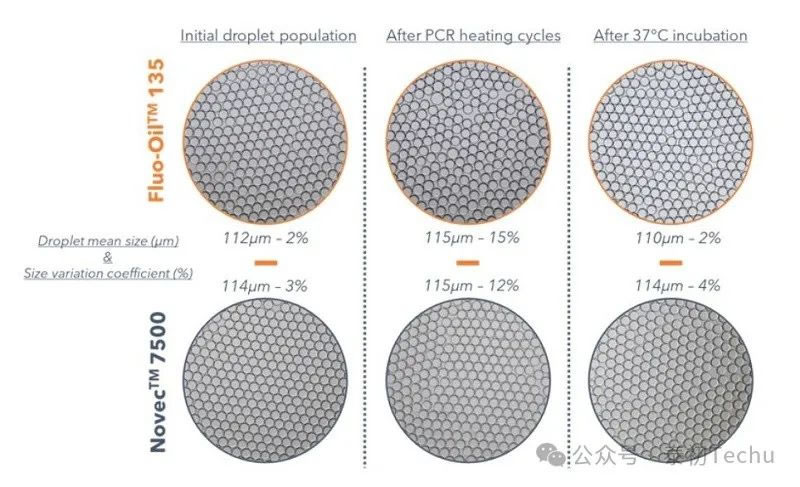

1. Droplet size and distribution

In Fluo-Oil 135 and HFE7500 oils, water droplets of similar size are produced. The average diameter of the droplets is 110 μm under the established flow rate parameters. The droplet size had a CV of 2.3% (Fluo-Oil 135 oil) and 2.9% (HFE7500 oil), respectively.

2. Droplet stability

Most research teams use droplet microfluidics for cell encapsulation or PCR applications. Therefore, stable droplets are produced by heating cycles of PCR and long-term incubation at 37°C. The choice of surfactant is critical, but the selection of oil is equally important to ensure reproducible experiments and the generation and preservation of monodisperse droplet swarms.

The stability of the droplets is tested from three aspects: first, the droplets are re-injected into the glass observation chamber; The second is the classic PCR thermal cycling process, which is 30 times, and each thermal cycle is 98°C for 10s, 50°C for 5s, and 72°C for 10s. The third is placed in an incubator at 37 °C for 3 days. 10,000 droplets were analyzed.

Conclusion:

Whether forming FluoSurf stable droplets in Novec HFE 7500 or Fluo-Oil 135, the average droplet size remains the same at generation after a PCR heating cycle or after 3 days of incubation at 37°C [approximately 110 μm (0.7 nL)]. In addition, droplet populations remain monodispersive. Based on statistical analysis, it was calculated that only 5% of the overall droplet size differs more than 10% from the average initial droplet diameter after the heating cycle.

Switching fluorine oil from Novec HFE 7500 to Fluo-Oil 135 has no effect on droplet stability.

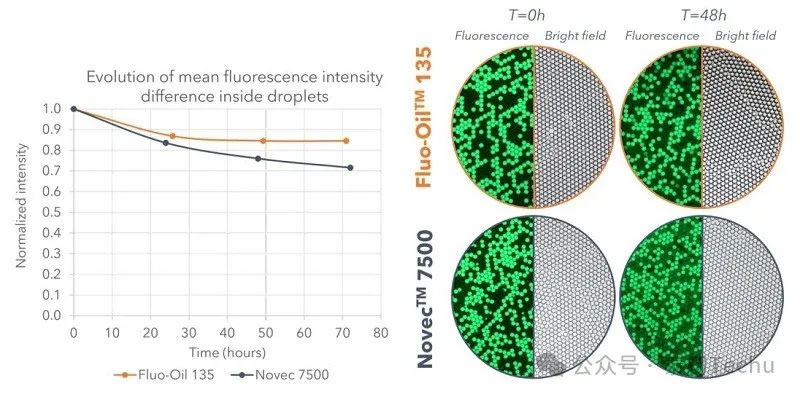

3. Molecule retention in the droplet

Droplet-based chemical or biochemical analysis relies on reagents to remain isolated in individual droplets. The exchange between leakage into the continuous phase and the droplets, even if low, can affect the integrity of the results, so molecular retention is an important parameter to consider when choosing fluorinated oils. Fluorinated oils are known to limit molecular exchange between droplets, so the effect of switching oils should be verified.

Two water-in-oil emulsions [“empty” (loaded PBS) and “full” (loaded fluorescein) droplets] are generated simultaneously, using Novec HFE7500 at a time and then using Fluo-Oil 135 as the continuous phase. Two mixtures, each containing two populations, were incubated at 37°C and photographed at different time points. The evolution of fluorescence intensity within the droplet was statistically quantitatively analyzed using ImageJ software.

Figure 3 shows the evolution of the difference in mean fluorescence intensity between the two populations (dye-loaded and empty

droplets) and associated fluorescence and brightfield pictures at the initial time point and after 48 hours.

Over the course of 24 hours, the leakage rate of fluorescein in the droplets produced by both fluorinated oils was similar (about 15% leakage) and remained constant for 135 days with droplets produced in Fluo-Oil 3. Conversely, after 24 hours, the leakage of droplets in Novec HFE7500 continued to decrease and reached around 30%. This poor retention performance for longer incubation times can be attributed to the slightly lower viscosity of the latter oil, which accelerates faster molecular exchange between droplets.

conclusion

For droplet-based microfluidic applications, switching from one fluorinated oil type to another can have a significant impact on the process of microfluidic experiments, especially on the efficient generation of droplets. In the case of Novec HFE7500 and Fluo-Oil 135, it has been confirmed that changing these two fluorinated oils has no effect on experimental conditions and results. When using Fluo-Oil 135 as a continuous phase, better retention of fluorescein within the droplets can even be observed.

Fluorinated Oil Fluo-Oil 135 is an effective alternative to Novec HFE7500 for droplet microfluidic applications.

Pair with FluoSurf Neat’s fluorinated surfactant, surface treatment hydrophobic reagent Fluo-ST3, to obtain repeatable, consistent experimental data.