Fluo-ST3 is a fluorophilic and hydrophobic surface treatment reagent consisting of fluoroalkyl silanes dissolved in a perfluoropolyether solvent. Fluo-ST3 is a transparent solution with low viscosity and low interfacial tension. After the surface of the object is treated, a uniform covalent thin layer is attached to the surface of the object, making the microchannel wall or surface both hydrophobic and fluorophilic. This treatment allows for better production of droplet microspheres and stabilized droplets in fluorine oil.

Fluo-ST3 is suitable for use with emulsifiers, fluorinated surfactants, various common droplet-forming oils, etc.

Advantages of Fluo-ST3 Hydrophobic Reagent:

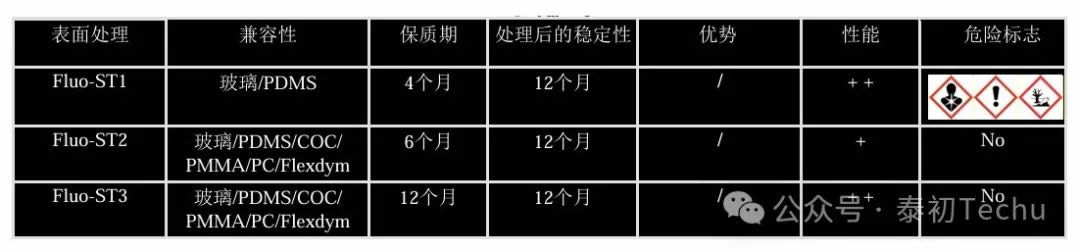

Comparison of Fluo-ST Series Hydrophobic Reagents

Fluo-ST3 storage conditions

Fluo-ST3 Hydrophobic Surface Treatment Reagent can be stored at room temperature for 1 year without loss of performance.

The ST3-treated chip can be stored at room temperature for 1 year without loss of performance.

Fluo-ST3 Usage Steps:

1. Clean the surface with isopropyl alcohol

2. Cover the surface with Fluo-ST3

3. Remove excess reagents.

4. Let stand for 30 s, then rinse the surface with argon gas;

5. Wipe/rinse the surface with fluorine oil and rinse with argon gas.

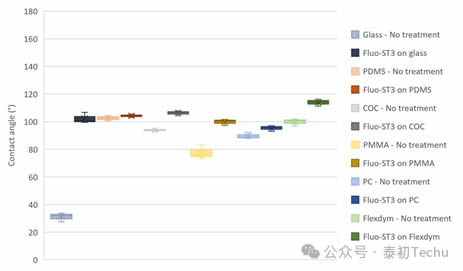

Test results

Regardless of the material being tested, the surface treatment improves hydrophobicity. It can completely replace Aquapel (Autoserv, Germany) for surface hydrophobic treatment of PDMS, silicon wafers, glass, etc.

For an example of a PDMS microfluidic chip:

以聚二甲基硅氧烷(PDMS)为原料,采用标准软光刻技术制备了微流控器件。通过光刻掩模在硅片上进行紫外曝光制备了SU-8抗蚀剂模具。在PDMS胶(Sylgard 184硅胶弹性体套件)中加入固化剂至最终浓度为10% (w/w),混合,倒在模具上。脱气几分钟,在75°C交联一小时后,将PDMS从模具上剥离,用0.75 mm直径的打孔器在PDMS片上加工输入和输出端口。用透明胶带从端口清除PDMS颗粒,用异丙醇冲洗,用加压氮气干燥。将PDMS板的结构侧与75 × 50 × 1.2 mm的玻璃显微镜载玻片(康宁)结合,将这两个部分暴露在氧等离子体中并将它们压在一起。最后,将Fluo-ST3疏水溶液注入到PDMS器件中(泰初科技(天津)有限公司),在微流体通道壁上形成一薄层疏水表面涂层,然后用氩气吹净疏水溶液。对于导电微流控芯片,PDMS器件被等离子体粘接到75 × 50 × 1.1 mm氧化铟锡玻璃的非导电侧。ITO玻璃的导电面用作反电极。通过使用低熔点焊料(#19铟锡金属)填充整个微通道,将电极集成到系统中。

Suggestion:

When treating PDMS chips with hydrophobic reagents Fluo-ST3 and Fluo-ST2, 10-30 chips can be processed at one time and set aside for backup. This saves a lot of time while ensuring the consistency of the PDMS devices used.

For an introduction to FluoSurf’s fluorinated surfactants, click here