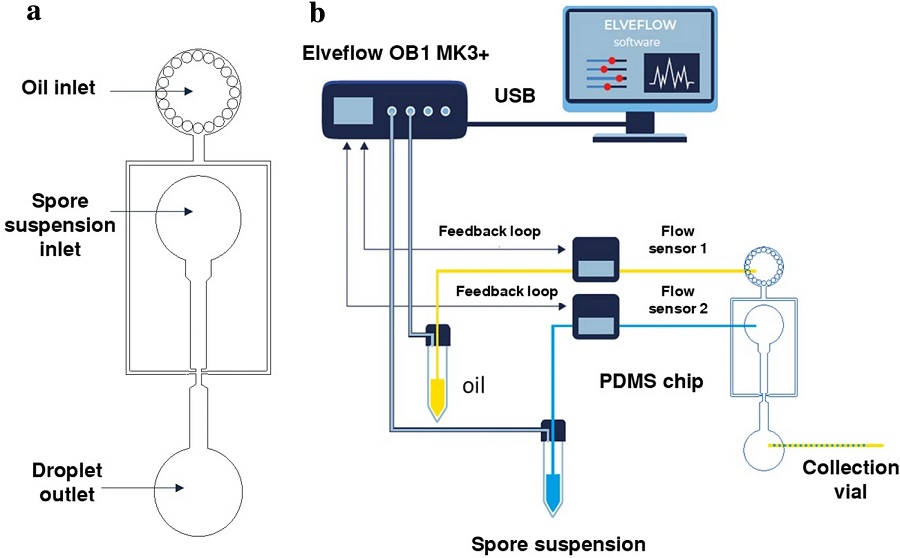

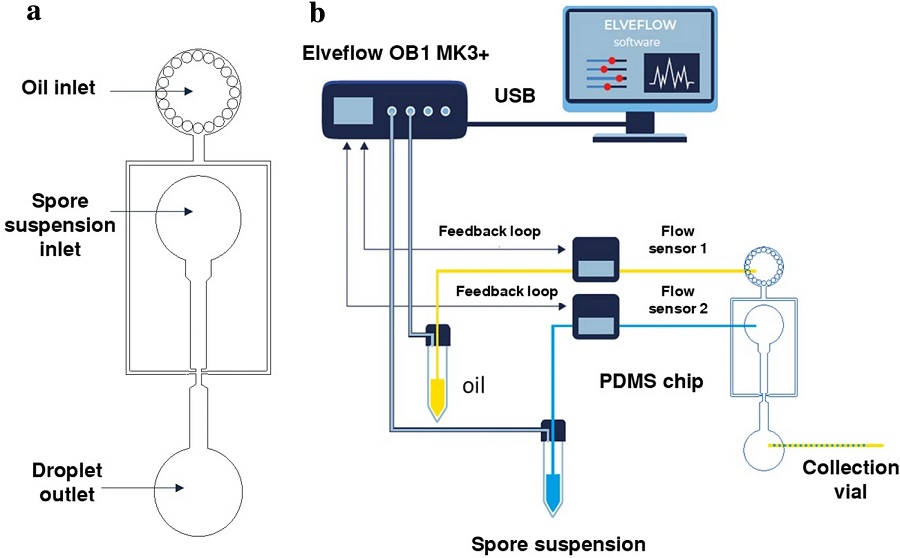

A microfluidic chip was created by soft-lithography technique. The chip was designed under the software AutoCAD 2018 (Autodesk, Inc) (Fig. 5a) and printed on a photomask by CAD/Art (CAD/Art Services, Inc, USA). A mold of SU8-2050 negative photoresist (MicroChem Corp, USA.) was prepared on a silicon wafer (Siltronix) by UV exposure (UV-KUB, Kloé, France) through a photomask and subsequent development (SU-8 developer; MicroChem Corp.). A curing agent was added to PDMS base (Sylgard 184 elastomer kit; Dow Corning Corp.) to a final concentration of 10% (w/w), mixed, and poured onto the mold. After degassing under vacuum, the mold was incubated for five hours at 65 °C. PDMS was then peeled off and inlets and outlets were punched with biopsy punch (Ø 0.75 mm; Eloise, France). The structured side of the PDMS was bound to a glass microscope slide (Corning) by exposing both parts to an oxygen plasma (Harrick Plasma) equipped with Equinox (BlackHole Lab, France). The microfluidic chips were treated with Aquapel (Autoserv, Germany) followed by HFE-7500 oil (Novec7500, 3 M). A spore suspension of a precise concentration (2 × 104 spores mL−1) according to Poisson Law54 (λ = 0.01) was prepared from 7–8 days old sporulating cultures of A. alternata in half strength PDB (Dutscher, France). The spore suspension was filtered using nylon filtration tissue NITEX, mesh opening 50 μm (Dutscher, France) and 0.1% Tween 20 (Sigma, Aldrich) was added. The reservoirs were filled with spore suspension and HFE-7500 fluorinated oil diluted with 1% surfactant (Emulseo, France) and connected to the microfluidic chip by OD 1/32″ tubing. The reservoirs were connected to the OB1 pressure controller (Elveflow, France) outlet to control flow rates through the ESI software (Fig. 5b). The droplet size for single spore encapsulation was optimized by applying different pressures to accommodate single spore.

PDMS微流控芯片通常采用软光刻技术,基本上主要有三个主要步骤:

1,加工SU8-2050模板

2,在SU8模板上复制带有沟道的PDMS片,然后把PDMS片和显微镜载玻片经过等离子清洗机处理后,键合在一起。

3,采用Aquapel或者Fluo-ST2疏水试剂处理PDMS芯片沟道,形成疏水性质,以增强油包水类型的液滴产生,并防止液滴融合和团聚。

4,(可选)用带有FluoSurf表面活性剂的连续相氟油7500注入到PDMS芯片沟道内,以降低分散相物质吸附到PDMS沟道的侧壁上。

本内容节选自文献

Droplet-based microfluidics platform for antifungal analysis against filamentous fungi

Iftikhar, S., Vigne, A. & Sepulveda-Diaz, J.E. Droplet-based microfluidics platform for antifungal analysis against filamentous fungi. Sci Rep 11, 22998 (2021). https://doi.org/10.1038/s41598-021-02350-8